Operation Market Garden, launched on September 17,1944 during World War II, was an ambitious Allied military operation aimed at ending the war by securing key bridges in the Netherlands and enabling a rapid advance into Germany. The operation combined airborne assaults with a ground offensive, making it one of the largest airborne operations in history. From a supply chain management perspective, the operation presents a case study in logistics planning, execution, and the consequences of mismanagement. This essay will explore the logistics of Operation Market Garden through the lens of supply chain management principles, analyzing key factors such as planning, transportation, coordination, and risk management.

1. Strategic Planning: Aligning Goals with Resources

One of the core principles of supply chain management is aligning strategic goals with available resources. In the case of Operation Market Garden, the strategic objective was clear: to secure a series of bridges along a 100-mile corridor through the Netherlands, creating a route for the Allied forces to enter Germany and cut off the Ruhr, the industrial heartland of the German war effort. This required tight coordination between airborne and ground forces, as well as swift logistical support to sustain the momentum of the advancing troops.

However, the planning of the Market Garden was rushed. The operation was devised in just a few weeks, leaving little time for thorough logistical planning. Supply chain management emphasizes the need for comprehensive resource planning, including inventory, transportation, and personnel. In Market Garden, the mismatch between strategic objectives and the logistics required to achieve them became evident. For instance, the plan underestimated the complexity of transporting heavy equipment and supplies across difficult terrain, which would prove crucial in the success or failure of the operation.

2. Transportation: Ensuring the Flow of Resources

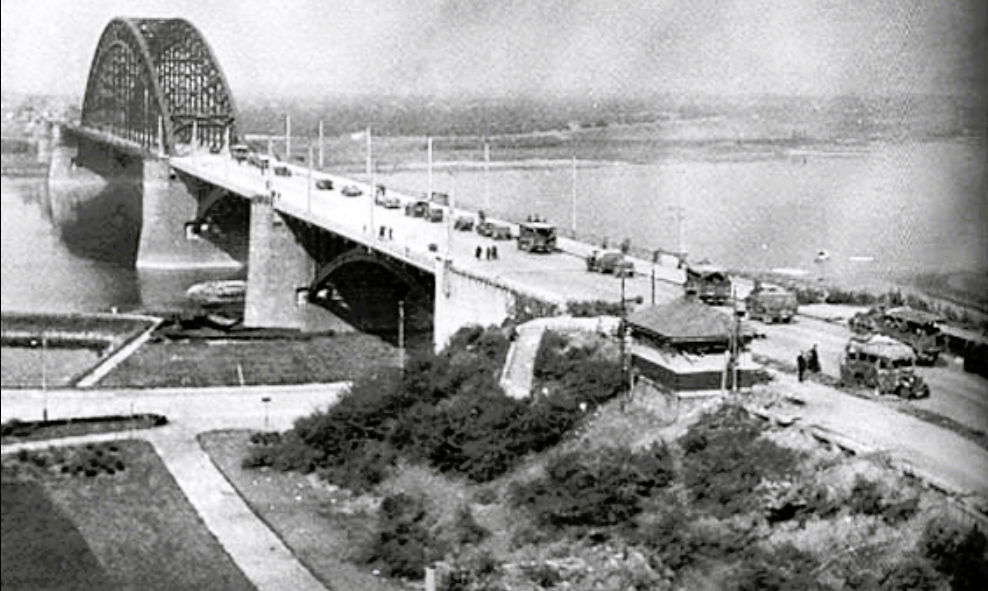

Transportation is a critical component of supply chain management, as it ensures the movement of resources from origin to destination. In Operation Market Garden, the transportation of troops, equipment, and supplies depended on two main components: airborne drops and ground convoys. The airborne component involved three Allied airborne divisions being dropped behind enemy lines to capture the bridges, while the ground component, led by the British XXX Corps, would advance along a single road to reinforce them.

From a logistics perspective, the reliance on a single road for transportation was a significant vulnerability. Supply chain theory emphasizes the importance of redundancy in transportation routes to mitigate the risk of bottlenecks. In Market Garden, the narrowness of the road, which became known as “Hell’s Highway,” limited the flow of reinforcements, supplies, and equipment. The road was frequently cut off by German counterattacks, slowing down the advance and creating supply chain disruptions. The inability to keep the supply lines open severely hindered the operation, as troops at the farthest bridge in Arnhem were left without sufficient reinforcements or supplies.

Additionally, air supply drops, intended to sustain the airborne forces, often landed in enemy-controlled territory or were too dispersed, illustrating poor coordination between the supply chain nodes (airborne forces and logistics planners). This highlights the principle that efficient transportation networks must be flexible and well-coordinated to respond to real-time changes, something the Allies struggled to achieve during the operation.

3. Coordination and Collaboration: Synchronizing Efforts

A successful supply chain requires effective coordination and collaboration across all stakeholders to ensure that resources flow seamlessly from suppliers to end-users. In Operation Market Garden, the complexity of coordinating multiple Allied forces (American, British, Polish) and the various components of the operation (airborne and ground) was a significant challenge.

The airborne and ground operations were not synchronized effectively, leading to delays and confusion. For example, the 1st British Airborne Division, tasked with capturing the Arnhem bridge, found itself isolated and cut off due to the slow progress of XXX Corps along Hell’s Highway. The delay in reinforcements arriving was a result of poor coordination between the ground forces and the airborne troops, exacerbated by communication breakdowns. Supply chain management teaches the importance of real-time information sharing and collaboration across the network. In Market Garden, the inability to maintain continuous communication between supply chain nodes led to inefficiencies and the eventual failure to secure the objectives.

Moreover, the lack of coordination extended to the handling of resources. Supplies were misallocated due to inaccurate information about the needs of frontline units. For instance, in Arnhem, British paratroopers were surrounded and running low on ammunition, food, and medical supplies, yet many of the airdrops missed their intended targets, landing in German-controlled areas. This failure in the last mile of the supply chain reflects the critical importance of ensuring that supply chain efforts are aligned with the tactical needs of end-users.

4. Risk Management and Flexibility: Anticipating and Mitigating Challenges

Risk management is a fundamental principle of supply chain management. It involves identifying potential risks, developing contingency plans, and maintaining flexibility to adapt to unforeseen challenges. Operation Market Garden, while bold in its ambition, underestimated several key risks that ultimately undermined its success.

One major risk that was not adequately accounted for was the strength of German forces in the area. Allied intelligence underestimated the presence of the German 9th and 10th SS Panzer Divisions near Arnhem, leading to the failure of the British 1st Airborne Division to hold the bridge. Effective supply chain risk management would have involved more thorough intelligence gathering and scenario planning to anticipate such obstacles.

Additionally, the operation lacked flexibility. The tight timetable for capturing the bridges left little room for error or delays. When XXX Corps encountered stiff resistance and logistical bottlenecks along Hell’s Highway, there were no alternative plans to reroute supplies or adjust the strategy. In supply chain management, maintaining flexibility is critical to responding to disruptions, yet Operation Market Garden’s rigid timeline and over-reliance on a single route demonstrated the dangers of a lack of adaptability.

5. Performance Measurement and Continuous Improvement

In supply chain management, performance measurement and continuous improvement are essential for optimizing processes and achieving long-term success. Market Garden’s failure offers valuable lessons in the importance of post-operation evaluation and the need for continuous learning from past experiences. After the operation, it became clear that the Allies’ logistics planning and execution were flawed, particularly in terms of transportation efficiency, coordination, and risk management.

A more robust system of performance measurement could have helped identify these logistical weaknesses earlier in the operation, allowing for mid-operation corrections. For instance, better tracking of supply flow and real-time data collection could have helped identify bottlenecks along Hell’s Highway sooner, enabling more proactive responses to supply chain disruptions.

Operation Market Garden, viewed through the lens of supply chain management principles, reveals the critical importance of strategic planning, effective transportation networks, coordination, risk management, and performance measurement in the success of large-scale operations. The operation’s failure can be attributed mainly to logistical miscalculations, including the over-reliance on a single supply route, poor coordination between airborne and ground forces, and inadequate risk management. For modern supply chain managers, the lessons of Market Garden serve as a reminder that even the most well-intentioned plans can fail without meticulous attention to the logistical details that underpin any complex operation.

Sources

https://www.nam.ac.uk/explore/market-garden

https://www.britannica.com/event/Operation-Market-Garden

https://www.liberationroute.com/stories/184/operation-market-garden

Donation

Your readership is what makes my site a success, and I am truly passionate about providing you with valuable content. I have been doing this at no cost and will continue to do so. Your voluntary donation of $2 or more, if you are able, would be a significant contribution to the continuation of my work. However, I fully understand if you’re not in a position to do so. Your support, in any form, is greatly appreciated. Thank you. To donate, click on the credit/debit card icon of the card you will use. If you want to donate more than $2, just add a higher number in the box left from the PayPal link. Your generosity is greatly appreciated. Many thanks.

$2.00

Leave a comment